How to Choose the Right Stainless Steel Wire Mesh for Your Needs?

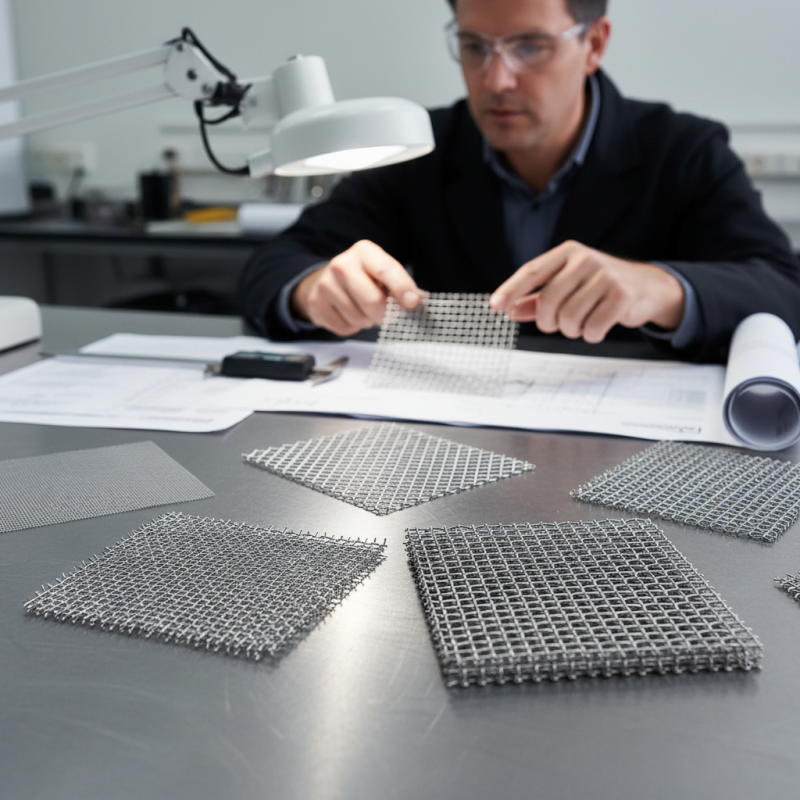

Choosing the right stainless steel wire mesh is essential for various applications. It can impact both performance and durability. Expert Mark Johnson from Mesh Solutions states, "The right selection can make all the difference in your project."

Different projects require different types of stainless steel wire mesh. Knowing the specific needs is crucial. Factors include width, wire diameter, and opening size. A small error in selection can lead to performance issues.

Many overlook the quality of materials. Some meshes may rust or degrade over time. Always ask for certifications and test reports. Remember, not all stainless steel wire mesh is created equally. The choice genuinely affects the longevity of your project.

Understanding the Different Types of Stainless Steel Wire Mesh Available

When looking for the right stainless steel wire mesh, it's crucial to understand the different types available. There are various grades, such as 304 and 316 stainless steel. Grade 304 is highly corrosion-resistant, suitable for many applications. However, it may not hold up as well in marine environments. On the other hand, Grade 316 offers superior resistance to saltwater corrosion. This is essential in coastal areas or chemical processing facilities.

Wire mesh also comes in different patterns and openings. A standard square mesh is versatile, found in filtration, sieving, and architectural applications. Meanwhile, crimped mesh may provide added strength and stability. A mesh with a finer opening is good for ventilation or security but may restrict airflow. Industry reports suggest that the choice of mesh can drastically impact performance. Choosing the wrong type may lead to issues like rust or inadequate support.

In some cases, less popular options like welded wire mesh can serve specific purposes. While they offer robust construction, they may not be as flexible as woven types. Certain applications may require customized specifications. It's essential to weigh these decisions carefully. Misjudging needs can lead to costly renovations or failures in functionality. Always analyze your requirements against the material properties available.

Key Factors to Consider When Choosing Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, several key factors come into play. The mesh type is crucial. Options include welded, woven, or custom styles. Each serves different purposes. For instance, woven mesh is versatile, while welded mesh offers strength. Think about the specific application.

Another essential factor is the wire diameter. Thicker wires provide sturdiness, which is ideal for structural support. However, finer wires allow for better filtration. It’s a balance between durability and functionality. Consider the environment too. Corrosive settings demand higher-grade stainless steel that withstands harsh conditions.

It’s easy to overlook the mesh opening size. Smaller openings filter out finer particles, while larger ones allow more airflow. Be mindful of your needs. You want effective performance but may miss some details. Review your choices carefully. Don’t rush the decision-making process; reflect on what works best.

Applications of Stainless Steel Wire Mesh and Their Specific Requirements

Stainless steel wire mesh finds applications across various industries. Each application has unique requirements, demanding careful selection. In the food industry, for example, mesh must be durable and resistant to corrosion. A report from the Stainless Steel World Conference indicates that 30% of food processing equipment now utilizes stainless steel mesh for its hygiene properties.

In the construction sector, wire mesh plays a crucial role in reinforcing structures. The demand for high-tensile strength mesh has increased by 25% in the past five years. This increase reflects a shift towards safer and more robust building practices. However, selecting the right type of mesh can be challenging. Incorrect choices can lead to structural weaknesses.

In filtration systems, wire mesh is essential for liquid and gas processing. The mesh must be capable of withstanding high pressure. A study highlighted that improper mesh selection contributes to 15% of filtration failures. This underscores the importance of understanding specific requirements for each application.

How to Choose the Right Stainless Steel Wire Mesh for Your Needs?

| Application | Mesh Size (inches) | Material Grade | Wire Diameter (mm) | Specific Requirements |

|---|---|---|---|---|

| Food Processing | 1/4" | 304 | 0.5 | Corrosion Resistant |

| Water Filtration | 1/8" | 316 | 0.3 | High Mechanical Strength |

| Architectural Use | 1/2" | 304 | 0.8 | Aesthetic Design |

| Mining & Industry | 1" | 316 | 1.2 | High Durability |

| General Use | 3/16" | 304 | 0.4 | Versatile for Various Applications |

Maintenance Tips for Ensuring Longevity of Stainless Steel Wire Mesh

Maintaining stainless steel wire mesh can extend its lifespan significantly. Regular cleaning is crucial. Dirt and debris can accumulate, leading to corrosion. A simple wash with warm soapy water can do wonders. Remember to scrub gently; harsh materials may scratch the surface.

Inspecting the mesh for damage should be routine. Look for signs of wear or rust spots. These might seem minor, but they can lead to bigger issues. If you spot any problems, address them promptly. Ignoring small flaws can turn them into costly repairs later.

Storage is also vital. Keep the mesh in a dry place to prevent moisture buildup. Avoid areas with high humidity. Covering the mesh when not in use can shield it from dirt and environmental factors. Small steps like these contribute to its durability. Don't overlook them.

How to Calculate the Required Specifications for Your Wire Mesh Needs

Calculating the required specifications for stainless steel wire mesh can seem daunting. Start by identifying critical factors such as aperture size, wire diameter, and mesh count. These elements dictate the mesh's strength and filtering capabilities. According to industry reports, the mesh count significantly influences filtration efficiency. Higher mesh counts lead to finer filtration but can compromise airflow.

Next, assess the application. Different uses demand different properties. For instance, food processing requires hygienic standards and corrosion resistance. A report by the International Stainless Steel Forum states that around 70% of applications benefit from 304 and 316 stainless steel grades due to their durability and resistance. Shooting for specs that meet these requirements is essential.

Finally, consider the environment where the mesh will be used. Factors like temperature, humidity, and potential exposure to chemicals can affect the selection. Reports suggest that 30% of mesh failures arise from not accounting for environmental conditions. Ensuring the wire mesh withstands these conditions can save costs. Taking these aspects into account when calculating specifications is vital. It helps in making a more informed choice.

Specifications of Stainless Steel Wire Mesh

This chart illustrates important specifications for selecting the right stainless steel wire mesh, including mesh size, wire diameter, aperture size, and open area percentage. Use these metrics to make an informed decision based on your specific requirements.