Why Choose Welded Wire Mesh for Your Projects?

In the construction industry, the choice of materials can greatly influence project outcomes. welded wire mesh is often highlighted for its durability and versatility. According to industry expert John Smith, "Welded wire mesh is not just a product; it’s an essential building block for any serious project." This statement underlines the significance of this material.

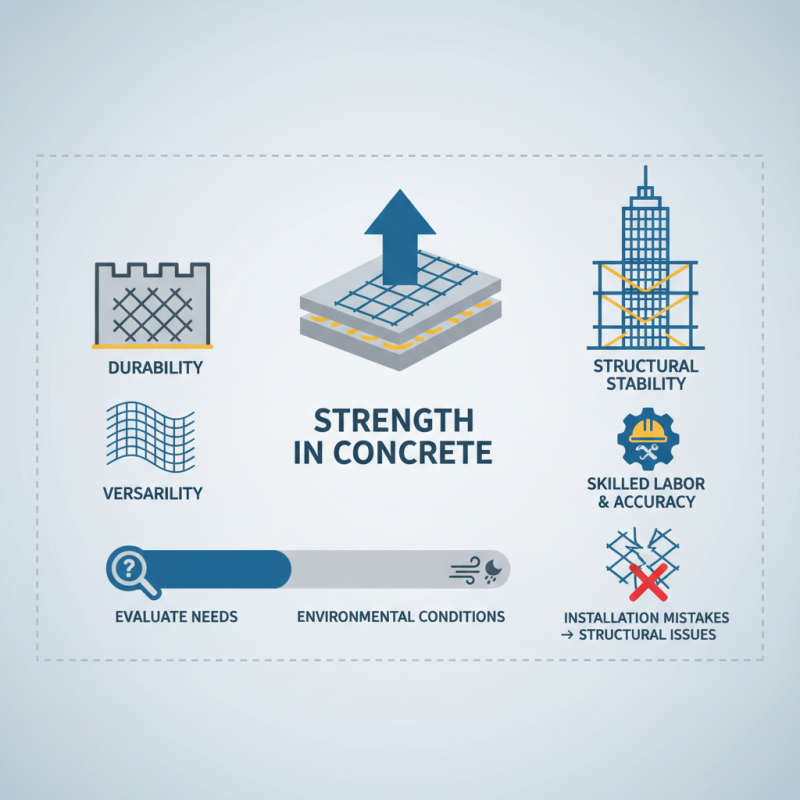

welded wire mesh combines strength with flexibility. It offers excellent support in concrete applications and ensures stability in various structures. However, not every project may require this kind of reinforcement. Potential users must evaluate their specific needs and environmental conditions.

Furthermore, while welded wire mesh is effective, challenges exist. Installation mistakes can lead to structural issues. The mesh must be cut and placed accurately. This requires skilled labor and can complicate the overall workflow. Interested parties should reflect on these factors when considering welded wire mesh for their projects.

Benefits of Welded Wire Mesh in Construction and Industrial Applications

Welded wire mesh is becoming a favored choice in construction and industrial projects. Its strength and versatility are key benefits. According to a report by Markets and Markets, the global welded wire mesh market is expected to reach USD 6 billion by 2026. This indicates a significant demand. Many builders appreciate its durability and cost-effectiveness.

The welded wire mesh offers excellent support for concrete structures. It enhances the load-bearing capacity. Safety is a critical aspect, as the mesh reduces the risk of structural failure. A study by the American Concrete Institute indicates that using welded wire mesh can improve crack resistance in reinforced concrete by up to 40%. This statistic underscores the mesh's role in enhancing construction longevity.

However, challenges exist. Some users report difficulty in cutting and handling large rolls. Not all projects may justify its installation costs. It's essential to evaluate the project's specific needs. While welded wire mesh provides numerous benefits, its application should be carefully considered to avoid over-engineering. Balancing cost and performance is key to optimizing its use in various environments.

Benefits of Welded Wire Mesh in Construction and Industrial Applications

Material Durability: Understanding the Strength of Welded Wire Mesh

Welded wire mesh is known for its durability and strength. It consists of intersecting wires that are welded at each junction. This design provides remarkable resistance to deformation under pressure. According to a study by the International Institute of Welding, welded wire mesh can withstand over 60% more tensile stress than traditional fencing materials.

The material used in welded wire mesh is often low-carbon steel, which is coated to prevent rust and corrosion. Research from the American Society of Civil Engineers indicates that properly coated welded wire mesh shows a lifespan exceeding 30 years, even in harsh environments. This longevity makes it a viable choice for various construction projects.

While the benefits are clear, there are some downsides. Installation can be challenging for beginners. Without proper tools and methods, the mesh could become misaligned. Additionally, costs may be higher than other materials, leading some to hesitate. However, the long-term savings in maintenance and replacements make it worth considering for many projects.

Cost-Effectiveness: Analyzing the Economic Advantages of Welded Wire Mesh

Welded wire mesh is a popular choice for many construction projects. Its cost-effectiveness makes it appealing to builders and contractors alike. The initial investment in welded wire mesh can be low compared to other materials. This price advantage doesn’t compromise quality, as it offers durability and strength.

One of the key economic benefits is its versatility. You can use welded wire mesh in various applications, such as fencing, concrete reinforcement, and agricultural projects. This adaptability can save money on materials. Additionally, the installation process is often quicker, reducing labor costs significantly.

Tips: Always consider the specific requirements of your project. Before purchasing, compare different specifications and sizes. This simple step can help avoid costly mistakes later. Think about transport costs as well. A lighter product might save money on shipping. While welded wire mesh has many advantages, it’s essential to double-check for any potential weaknesses in the project design. Overlooking these details might lead to unexpected challenges.

Versatility: Exploring the Various Uses of Welded Wire Mesh in Different Industries

Welded wire mesh is an adaptable material used across many industries. Its design allows for strong structural support while maintaining flexibility in application. The mesh can be found in construction, agriculture, and even crafting. In construction, it reinforces concrete to enhance durability. You’ll often see it in sidewalks or buildings.

In agriculture, welded wire mesh serves as fencing. It keeps livestock secure while allowing for airflow. Some farmers use it to protect crops from pests. Its versatility extends to crafts too. Artists and DIY enthusiasts find countless uses for it, from garden trellises to decorative projects. Often, it is easy to work with, yet choosing the right gauge is important.

However, issues arise when the mesh is not installed correctly. Poorly placed fencing can lead to escape routes for animals. In construction, a miscalculation can compromise strength. Experimenting with this material can result in trial and error. The challenges are worth reflecting upon for better results in future projects.

Why Choose Welded Wire Mesh for Your Projects? - Versatility: Exploring the Various Uses of Welded Wire Mesh in Different Industries

| Industry | Application | Material Used | Benefits |

|---|---|---|---|

| Construction | Reinforcement of Concrete | Galvanized Steel | High strength, corrosion resistance |

| Agriculture | Livestock Enclosures | Stainless Steel | Durability, animal protection |

| Landscaping | Garden Fencing | PVC Coated Wire | Aesthetic appeal, corrosion resistance |

| Security | Perimeter Fencing | High Tensile Wire | Strength, deterrent factor |

| Transportation | Railway Track Support | Carbon Steel | Load distribution, stability |

Compliance and Standards: Overview of Industry Regulations for Welded Wire Mesh

Welded wire mesh plays a crucial role in various projects, and understanding compliance and standards is essential. Many industries follow regulations to ensure safety and quality. Welding processes and materials used must meet specific criteria. This helps to maintain structural integrity and performance.

Regulations often differ by region. It’s important to check local guidelines. The standards help to determine wire diameter, mesh opening size, and welding quality. The correct specifications can enhance project durability.

Tip: Always ask suppliers about compliance certificates. This guarantees that the material meets industry standards.

Sometimes, projects may overlook these regulations. This can lead to problems down the line. It’s wise to consult experts or industry resources early in your planning. A misstep here can compromise safety and quality.

Tip: Regularly review updated standards. They can change based on new research or technologies. Staying informed protects your investment.